Plastic Recycling & Washing machine

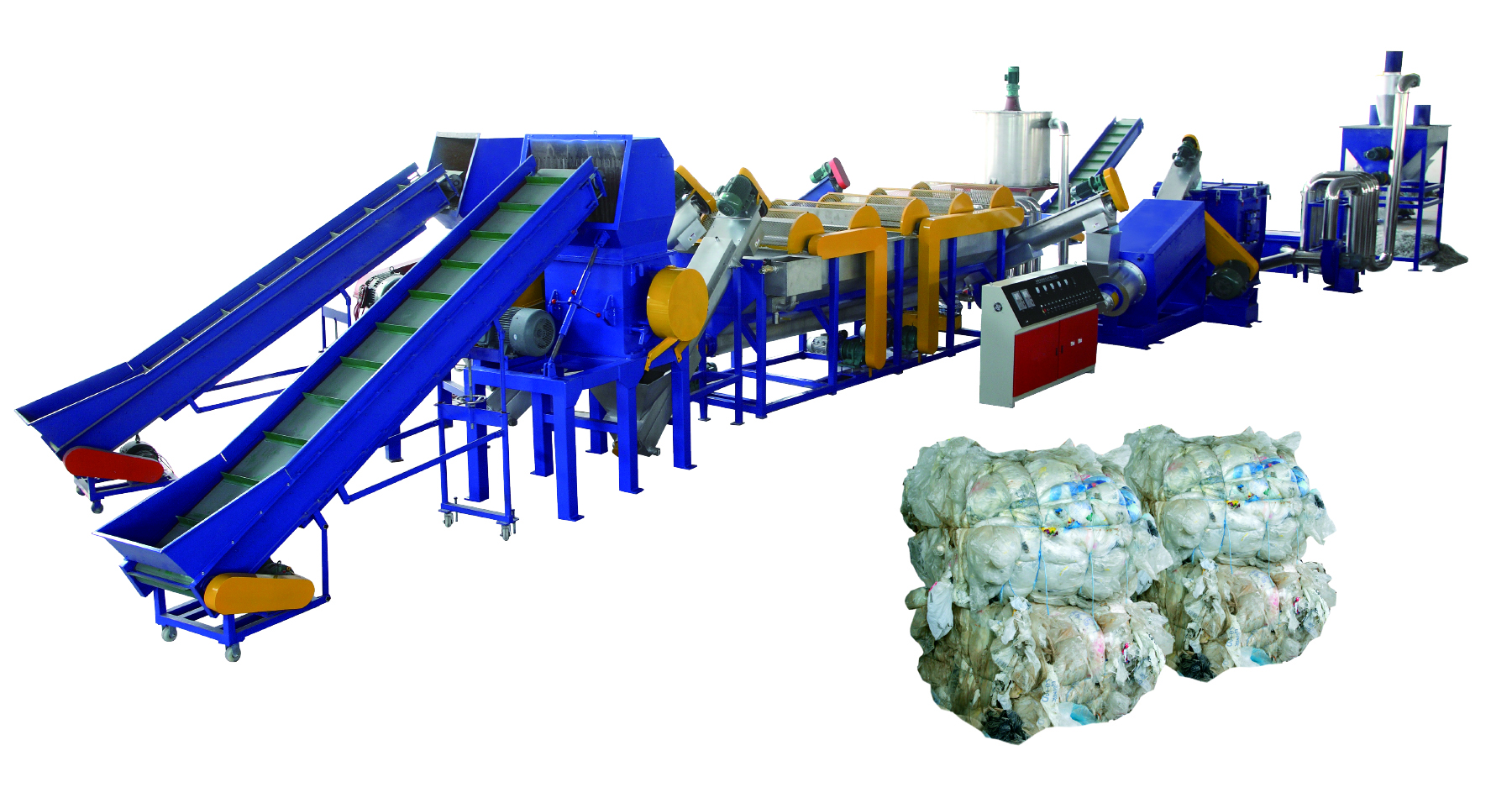

HDPE PP PE Film Washing Machine

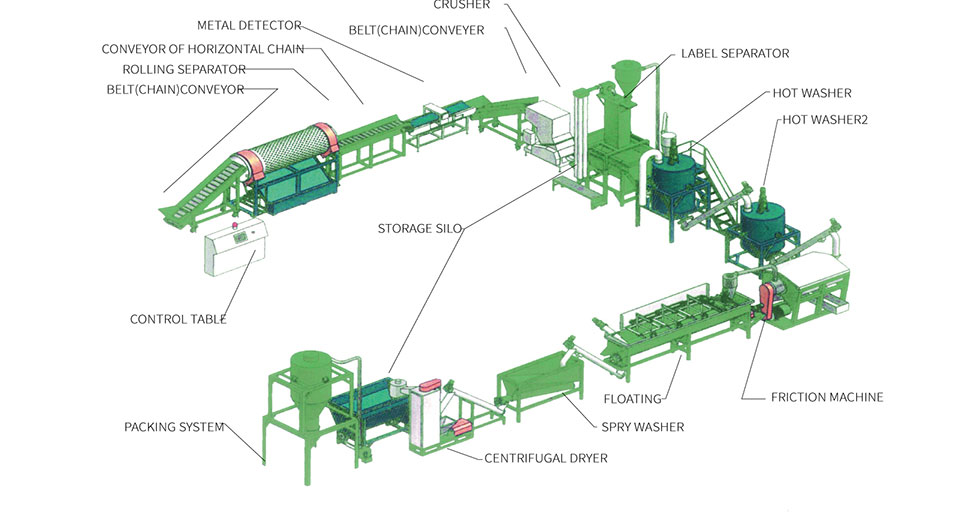

Metal detector

Fixed on belt conveyor. On-demand configuration.

Metal detector

Fixed on belt conveyor. On-demand configuration.  Crusher

According to the output and product ,equipped with different types of equipment

Crusher

According to the output and product ,equipped with different types of equipment  High Speed Friction washing machine&Rinsing washing tank

According to the cleanliness of the product。

High Speed Friction washing machine&Rinsing washing tank

According to the cleanliness of the product。  Blowing Machine/Pipeline Dryer/Heating Oven

Blowing Machine/Pipeline Dryer/Heating Oven  Vertical Round Storage hopper

Vertical Round Storage hopper Description

PE film washing line can be used to make granules from recycling waste and dirty PE,PP, LDPE, PS, HDPE material.

This machine can automatically work, only need three or four people operate easily, high capacity, low energy consumption. effective design and so on.

In order to improve capacity and quality of final product, we can change technological process according to the requirement of different material.

Materials

Plastic film for a washing line

Specification

| Capacity (kg/h) | 250-300 | 450-500 | 900-1000 | 1800-2000 |

| Belt conveyor | ||||

| Motor Power(kw) | 2.2KW | 2.2KW | 2.2KW | 2.2KW |

| Length | 4500mm | 5500mm | 5500mm | 5500mm |

| Metal Detector | ||||

| Size(mm) | 1200*800 | 1200*800 | 1200*800 | 1200*800 |

| Crusher | ||||

| Motor Power(kw) | 37kw | 90kw | 90kw | 110kw |

| Screw Feeder | ||||

| Motor Power(kw) | 1.5KW | 2.2KW | 2.2KW | 2.2KW |

| High speed Friction washing machine | ||||

| Motor Power(kw) | 30KW | 37kw | 55kw | 55kw |

| washing tank | ||||

| Size(mm) | 6000*1000mm | 6000*1600mm | 6000*1800mm | 8000*1600mm |

| Screw feeder | ||||

| Motor Power(kw) | 1.5KW | 2.2KW | 2.2KW | 2.2KW |

| Film Squeezing machine | ||||

| Motor Power(kw) | 75KW | 90kw | 185kw | 185kw |

| Pipeline | ||||

| Capacity (kg/h) | 250-300KG/H | 450-500KG/H | 900-1000KG/H | 1800-2000KG/H |

| Storage Hopper | ||||

| Volume | 1m³ | 1m³ | 1m³ | 5m³ |