Plastic Granulating Machine

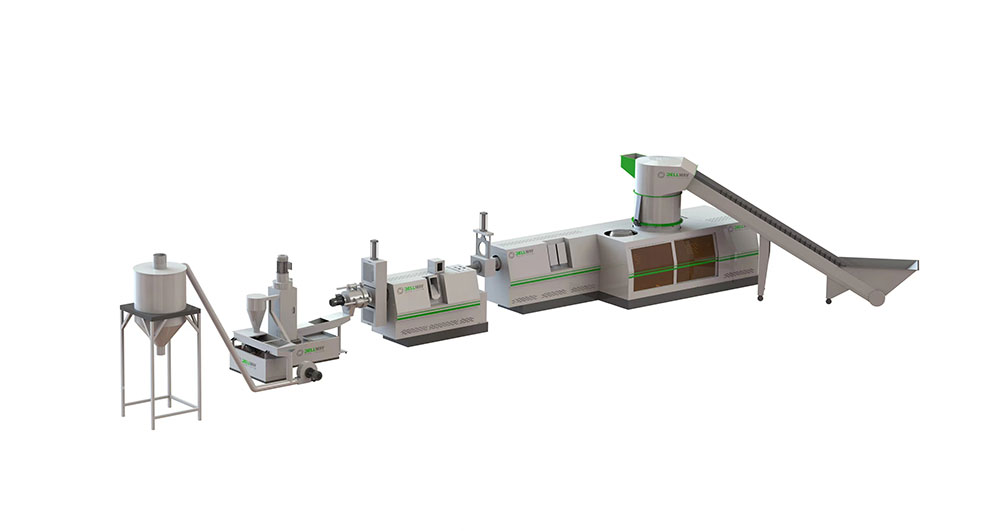

Plastic film double stage granulating machine

Feed system

Material for screw loader :Stainless Steel

Feed system

Material for screw loader :Stainless Steel  Extruder

Process: Feeding, melting, conveying, extrusion, cooling, curing.

Extruder

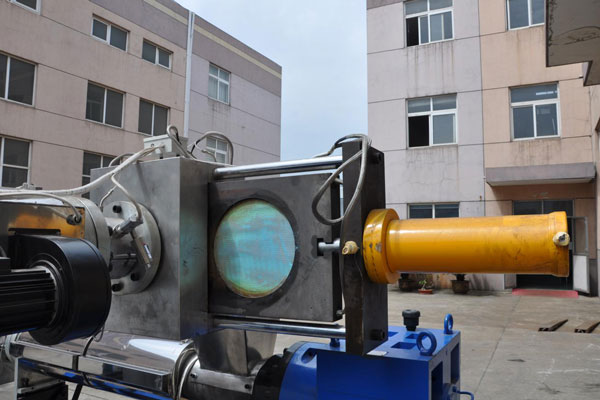

Process: Feeding, melting, conveying, extrusion, cooling, curing.  Hydraulic screen exchanger

Function: filter impurities The filter screen should be changed regularly

Hydraulic screen exchanger

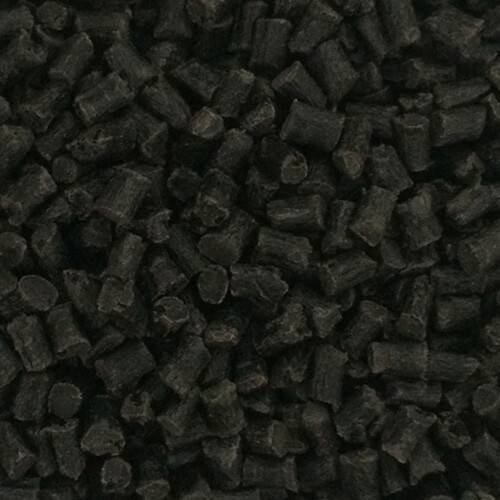

Function: filter impurities The filter screen should be changed regularly  When the molten polymer is extruded out of the die, it is cut into pellets by a granulator that rotates at a high speed

When the molten polymer is extruded out of the die, it is cut into pellets by a granulator that rotates at a high speed  1:using the principle of centrifugal drying and hot air drying, high drying efficiency;

2:the use of foot brake device, can quickly stop the rotary cylinder. 3:The dehydration basket is made of stainless steel.

1:using the principle of centrifugal drying and hot air drying, high drying efficiency;

2:the use of foot brake device, can quickly stop the rotary cylinder. 3:The dehydration basket is made of stainless steel.  Vibrating screen

Screening of qualified products

Vibrating screen

Screening of qualified products  Pipeline blowing drier

Pipeline blowing drierDescription

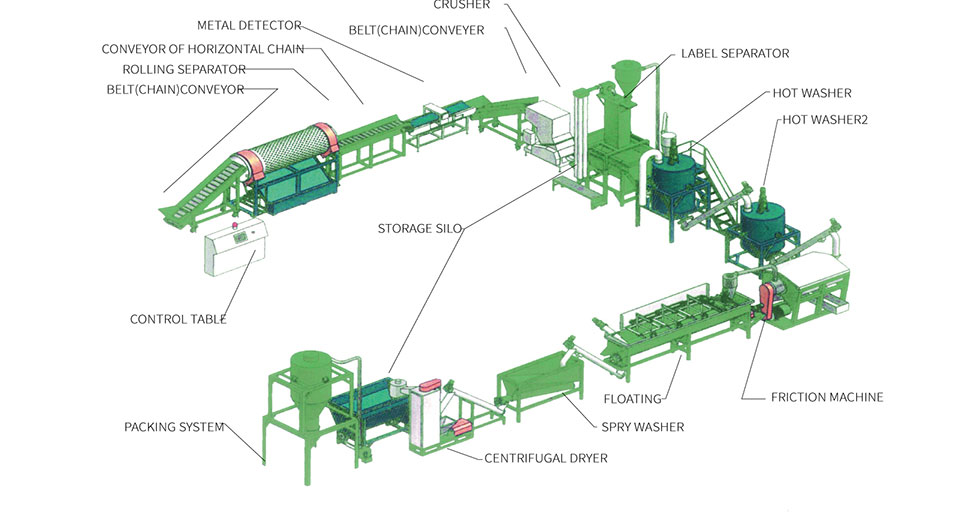

Double-step plastic granulating machine could Extruding the waste plastic into granulator,cooling and cutting. Waste plastic materials included: polyethylene (greenhouse film,PET bottle, lined bag) or Polypropylene(old film bag, packing belt, bundle rope, non-woven fabrics). This Double-Step Granulating Machine used widely,is preferred models of the Plastic Recycling Industry.

Materials

Crushed PP woven bag

PP Woven Bag

PE Film

PE Agricultural Films

Specification

| Model | SJ100-120 | SJ120-135 | SJ135-150 | SJ150-160 |

| Belt Conveyor | ||||

| Motor power | 1.5KW | 1.5KW | 1.5KW | 2.2KW |

| Agglomeration machine | ||||

| Main motor power(kw) | 110kw | 160kw | ||

| Capacity(kg/h) | 450-500 | 900-1000 | ||

| Volume | 600L | 1000L | ||

| Rotary blade | 4PCS | 4PCS | ||

| Fixed blades | 8PCS | 8PCS | ||

| Material of blade | 9CrSi | SKD11 | ||

| Main Extruder | ||||

| Motor power | 90KW | 110KW | 160KW | 135KW |

| Screw diameter(mm) | 100 | 120 | 135 | 150 |

| L/D | 30-34 | 30-34 | 30-34 | 30-34 |

| Main motor power(kw) | 90 | 110 | 132 | 160 |

| Screen Exchanger | ||||

| Screen diameter | 240mm | 270mm | 300mm | 320mm |

| Hydraulic Station | ||||

| Motor power | 2.2KW | 4KW | 4KW | 3KW |

| Second Extruder | ||||

| Motor power | 22KW | 45KW | 45KW | 45KW |

| Screw diameter(mm) | 120 | 135 | 150 | 160 |

| L/D | 10:1 | 10:1 | 10:1 | 10:1 |

| Capacity(kg/h) | 200-250 | 300-350 | 350-400 | 400-500 |

| Main motor power(kw) | 22 | 30 | 37 | 45 |

| Line length(m) | 12 | 14 | 15 | 16 |

| Screen Exchanger | ||||

| Length(mm) | 200mm | 300mm | 300mm | 400mm |

| Hot-cutting System | ||||

| Main motor power(kw) | 1.5KW | 1.5KW | 1.5KW | 3KW |

| Centrifugal Drier | ||||

| Main motor power(kw) | 4KW | 7.5KW | 7.5KW | 7.5KW |

| Storage Hopper | ||||

| Main motor power(kw) | 1.5KW*2 | 3KW | 3KW | 3KW*2 |